Adopting momery system for unexperted poewring off

and auto matic restoring of all the settings after restarting.

Embedded operating system base on Linux, dedicated machine for special use,

natural immunity to various computer viruses.

- Superiority

- Spesifications

Brand New Structure Design

1. Monolayer mainboard

2. Dual power supply

3. Multiple protection circuits

4. modular optical electric system

User Friendly man-machine interaction system

1. Clean and tidy for easy operation

2. What you see is what you get operation system

3. Air cooling enabling mainterance free and longer lifetime for laser source

Brand new main-machine interaction

1.Nice vision design

2. color screen with high resolution

3. Clean and tidy with all functions earily operated

4. Enhanced and simplitied message creeting system

5. Multi-language supponted

6. Multi-format of messages adopted:SHX, TTF font, logo, all codes (2D, barcude, QR, etc) serial number

7.Automatic date and time sheifting

8. Controllable line,reverse and traverse adjustment,and etc.

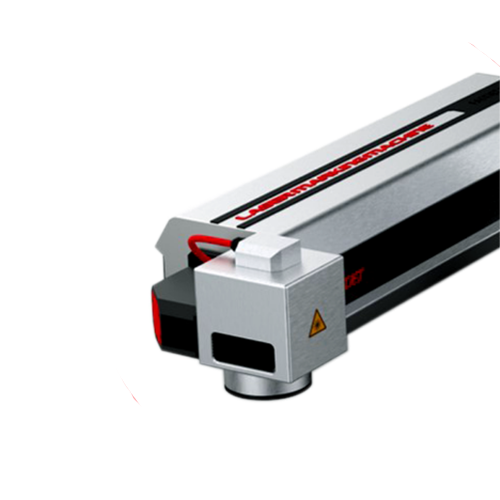

Newly designed printerhead

1. Compact and light, easy to carry and installed

2. High gacity and lastest technology call laser source adapting to most macterious in most industries.

3. Flexiblely adjusted bracket enabling easy installtion in different production lines.

Spesifications

Marking speed

Up to 2,000 characters/second

Line speed

Up to 200/min

Focus options

Standard F160(100x100)

Optional F100(70x70), F210(140x140),

F254(170x170), F300(220x220)

Wave lengths

355nm

Marking format

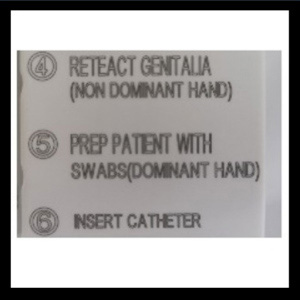

Standard industrial fonts (Type1 Windows®TrueType®) and single line font

Machine readable codes (OCR, 2D matrix, etc)

Bar codes: code128A, code128B, code128C, code39, code93,

QR-Code, Data Matrix, Aztec-Code, Han Xin-Code

Graphics, Logos, symbols, etc

Linear, circular, angular, reverse, rotate sequential and batch numbering

Automatic date, layer and time code, real time clock

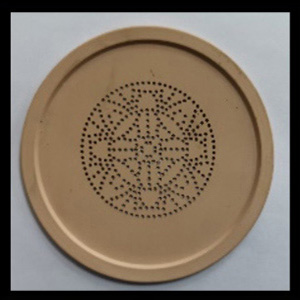

Dot model will be faster for marking

Laser tube

Solid-state UV laser

Beam deflection

Steer beam with digital high-speed galvanometer scanners

User interface

Personalized touch control screen, humanized operation, easy to learn

Maximum marking and line speed is application dependent

Communication

UDP,TCP/IP and RS232

Inputs for encoder and product detector triggers

4 inputs/4 outputs for start/stop signals, machine/operator interlocks, alarm outputs; in addition to the safety circuits

Customer-specific solutions available

Integration

Flexible beam delivery options (beam extension unit/beam turning unit)

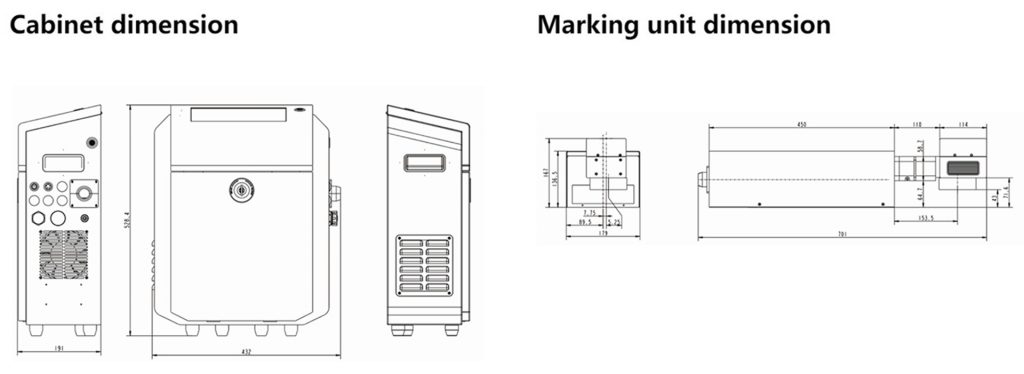

Electrical requirement

110-240 VAC (To be noted when ordering),〜50/60 Hz,

1 PH,0.70kW / 2PH,1.50kW

Cooling system

Air cooled

Environment

Temperature 5-40° C ⑷-104° F)

Humidity 10%-90%, no condensing

Sealing and safety standards

Cabinet: IP54 standard

Marking Unit: IP54 standard

Weight

Standard unit: approx. 28kg

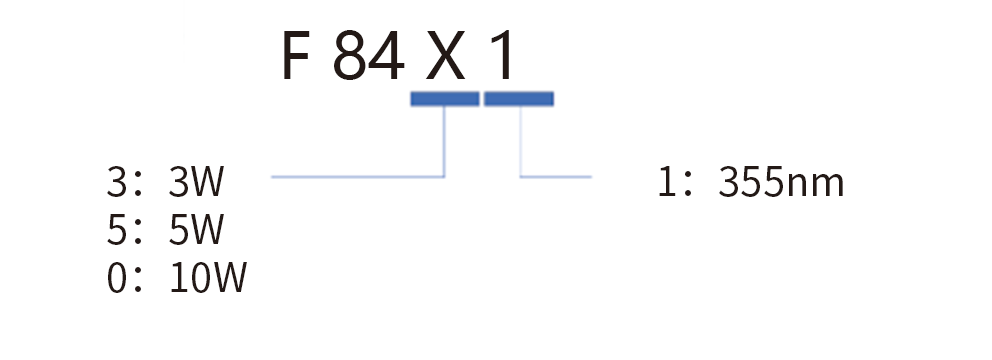

Specific model